Below, you’ll see a botched job one of my students did with a pattern we have in

the shop. We could speculate about what went wrong for him, but I am really just

showing what my principal had in mind when she asked me for a coin. She remembered

that we have a pattern for a big coin. She said that the head of our school board

would be flipping a coin before homecoming. She thought a big coin would be nice,

and indicated with her hands that she remembered it being about 3 inches across.

She wondered if we could have a student make one that says Chix on one side and

Dux on the other. I agreed that we could do it. That’s how this got started.

I printed out a logo the right size to fit on the inverted coffee mug.

Then I cut the wax away. This took about an hour.

That was Saturday night.

The next day, Sunday, I spent about 5 hours whittling away wax that didn't look

like a chick.

This was a lot harder than I thought it would be.

I could see that this might work. But I was not satisfied with the quality of

the detail. I have a lot of respect for real artists. I think they would have been

done with both by now.

Then, I started the Dux logo.

I was surprised how difficult the block letters were.

I kept working on the patterns, when time allowed, until Wednesday, October 5. I

planned to pour the brass Thursday afternoon. During the day on Wednesday, I replaced

the thermocouple in the kiln and got that working. Some heating elements were burned

out. I had replacements, but decided not to tackle that job yet. I also welded up

a small rack to hold the flasks up off the kiln floor. And I welded up a couple

flasks, 8” x 8” x 5” deep, out of ¼” plate.

It’s very difficult to discern the surface of the wax in these pictures, just as

it is in actual full view. The wax I have is translucent. Dirt from my fingers would

mix in, and cracks in the wax would show white through the clear parts. I was constantly

rotating the patterns under the light to try to get a fix on the surface. I was

surprised how difficult those block letters were to produce.

Around 11pm, I mixed the ceramic. I discovered before, with a test pattern, that

simply inverting the mug and pressing into the mud would trap air under the cup.

Even a small bubble would be a big problem. I averted this bubble problem thusly:

I poured wet investment onto the patterns, as they are positioned above. I tapped

the mugs several times to jar bubbles loose from the patterns. I allowed the mud

to set for about an hour. Then I filled the flasks with investment and mixed that

up with water. I took the mugs with the half-inch or so of set up investment attached,

and inverted them into the flasks. I allowed this to set for another hour. So, about

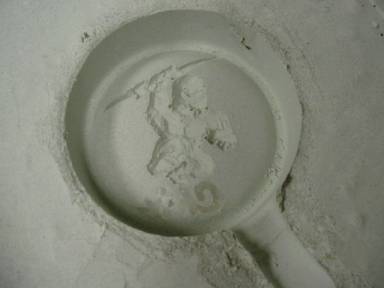

2am I pulled the mugs out of the investment to see what kind of impression I had.

I was pleased.

This picture does not show detail as clearly as you would see in real life, but

it turned out adequately, I thought. You can see a couple small bubbles, but I could

chip off the resulting metal after casting.

With the one below, you can see that some of the wax pulled off and stayed in the

mold (text and part of the lightning bolt). I figured I could just burn this out

and that I wouldn’t need the wax pattern after my pour.

I took these to Zeeland on Thursday morning and heated them in the kiln at 300º.

I expected to have to cook at this temperature for at least five hours, to dry out

the molds. It would take a little longer to burn out the wax. So, I was expecting

to put off pouring the metal until Friday. After a couple hours, I looked inside.

What I saw stunned me.

It was like an evil trick. I've had cracks before, but only with blocks that were

so hot for so long (30 hours) that the steel burned away around the mold. (I usually

use 18 gage). This was only 300 degrees for only two hours, and the cracks were

only in the most critical place.

Frustrated, stunned, baffled. I was too tired to panic. (Three or four hours per

night is what sleep I've been getting lately.) I might have time to rework the wax

and try again, but I needed to know what went wrong.

At first I suspected the investment. But that didn't sound reasonable. Maybe I used

more water this time, but I couldn't think of anything else I did differently. Hmmm...

After an hour or so, I realized what caused this problem.

It was the layers I produced by mixing the ceramic twice. They didn't adhere! The

thin layer I laid on the pattern buckled loose. Of course!

Even though time was running out, and I wouldn't be able to do any more work on

this project until the weekend, I was much relieved to know what went wrong.

I picked up a can of silicone spray. I'd try that as a release agent. I work late

in Grand Rapids on Friday, as I did on Thursday. Saturday, I work in GR from noon

till 2:00. But I found time that weekend to rework the wax and make new molds.

nothing's easy.

Anyway.. the problem I had with my investment involved layers. I wanted to avoid

them, but I still had the problem of cupping air under the pattern. My wife, Michelle,

came up with this idea, (below). I sunk the cups into dirt so that the investment

wouldn’t cover the cups entirely. (I dug 3’ and couldn’t find sand at home.)

I thought the draft (angle the sides make with the vertical) would allow the mold

to fall right out, when inverted after setting. That didn’t happen. I had to cut

the pails. I learned that pails from ACE Hardware have a heavy wire around the mouth,

under the plastic.

I tried something else different. I sprayed silicone onto the pattern before applying

the mud. I wanted the wax to release easily. It didn’t help.

You can see that the wax stuck in the mold. I dug this out to save it, just in case.

But it wasn’t worth it. The silicone made the wax hard to work with.

The duck turned out pretty good – for a second try. These are both second tries.

I wouldn’t have expected the wax to do more than a single mold.

I was going to race down to Zeeland on Saturday, but decided to wait until Sunday.

I had time. The homecoming game wasn’t until Friday.

On Sunday, I set the blocks into the crucible. I was a bit uneasy because the blocks

were not inside flasks. I remember that this stuff cracks when it gets hot. I thought

I would try to keep the temperature down. After all, I wasn’t burning out any wax.

I only wanted to dry the blocks out. I figured that since the inside of the blocks

wouldn’t get any hotter than 212°, as long as there was water inside, setting the

kiln for more than 300° would be unnecessary. So that’s where I set it, and left

the blocks overnight. (When I burn out wax, the temperature goes to 1,500° for more

than a day.)

You see (above) the crane I made three years ago for my pig Peg. It’s on wheels.

I’m using it to hold the kiln door open. Some of the hardware and most of the heating

elements to the kiln have been ruined by thermal shock. I understand that opening

the door to a hot kiln is destructive. It is also probably not right to keep turning

the thing on after it shuts itself off, as it does when it reaches its set temperature

(for me, usually above 1,500°).

When I retuned on Monday, I kicked the temp up to 500°. At the end of the school

day, I figured they must be dry. I was, however, a bit uncomfortable about color.

I remembered this stuff turning white, and mine were darker than that. I figured

that the dirt might have discolored things. I discovered the truth the hard way.

I got a student (Bill Machiela) to help me pour the brass. As soon as we filled

the first mold, I could tell we had problems. The metal was agitating. Steam was

bubbling up into the metal. I had us spill the rest of the metal into billets and

put the other mold back into the kiln. I raised the temperature to 750°.

You can see the sad results below. The black spots are holes left by steam. The

one behind his head goes almost all the way through. So, I needed to make a third

mold for the duck. This was Monday.

The mold cracked with the hot metal, but didn’t spill any.

When I left school for my grad class, I looked into the kiln. I noticed the mold

was turning white. I was glad to know what the problem was, and that I could trust

that dark molds were not dry.

After my evening grad class, I went home and (at 10 PM) worked up the wax for another

duck pattern. Working with that silicone was a problem. I wished I hadn’t tried

using it. Then, I went outside and mixed up another batch of investment in another

pail. In the morning, I loaded all my stuff. In case of another problem, I wanted

to have everything at school.

On Tuesday, I put the new duck mold into the kiln with the chick mold, and turned

the heat back on to 600° (the kiln shut itself off). I waited until the end of the

day to pour the chick mold. I was a bit concerned because small parts of the mold

looked dark. But I reasoned that it couldn’t possibly be damp after two days in

the kiln at temperatures ranging up to 750°. I talked about it with some students,

but decided to pour. You can see that I had the same problem, although not as bad.

There are holes, and a lot of the detail is missing.

I cranked the heat up in the kiln to 1,500°

I was feeling desperate. I needed to make another chick mold, and the wax was getting

real hard to work with. I also was afraid of cracks at the high temperature.

I thought I would reinforce the next mold, to be safe. I bent up some expanded metal.

Then I put it in the pail. This looked smart. You can see the dirt in the wax –

I’ve reworked this too many times. It looks worse each time.

I called Michelle (about 8PM). She thought I would be smart to make a spare duck

mold too – in case something happened to the one in the kiln. I agreed. It would

take me another hour or two, but I better do it. I decided to make a spare chick,

too. I would mix the mud for both at the same time.

While working on the duck wax, I noticed that a crack developed along the top of

the new chick mold. I didn’t realize what was going on, though, until I cut the

mold out. The “reinforcing” actually caused the mold to break. And it wasn’t even

hot yet.

You can see that hairline crack entering the light part, to the right. This looks

bad.

I had already thought about making yet another chick mold. But the wax is getting

real bad, with all that dirt and silicone.

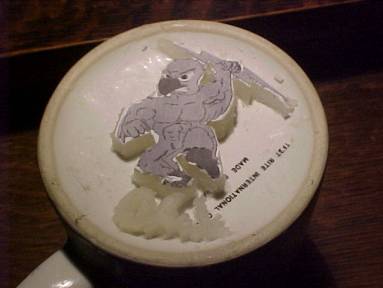

This is what was left on the mug.

I got it back together again. I mixed up mud for another mold. I’m loosing track

of how many this is. Let’s see.. there’s a duck mold in the kiln, and I’m making

another one for a spare. Then there’s this messed up one and I need a spare now

for this too.

I reworked that wax. This is getting hard.

I was out of pails, so I made one. I’m using a spot welder, below.

Right after pouring the mud into the last two molds, I ran to Lowe’s. I got there

just as they were closing (10 PM) and picked up a bag of hose clamps.

This might help.

This actually looks better than anything I’ve tried. I probably should have done

them all like this.

I cut the steel off with a plasma cutter. That was stupid. I got the cup real hot

doing this. It fused with the investment and I had a lot of trouble getting it out.

The wax all came off in the mold. And it was warm. It wasn’t going to be any more

use. So this will be my last chance, (didn’t I say that a week ago?)

<

I took a look at the duck I still had in the kiln. After heating it up, (and opening

the door) I noticed cracks. I wanted to put some hose clamps on it, so I let it

cool and took it out. Then I saw lots of cracks. It was just too fragile to mess

with. I put it back in and decided to try and see what happens. I do have a spare

now.

This is the same cracked mold. There's a crack around the ring the mug made, to

the left, but you can't see it in this picture. I could tell you what the dark color

around his glove means.

This is the last duck mold.

The same mold, with wax removed. (I sure got a lot of miles out of that wax!)

The last duck mold has no reinforcing, so I put clamps around it. I'm afraid that

they will dig in and break the mold as it heats. I put steel shims under the turn

buckles.

Here's my last duck mold, again, ready for the kiln.

I had to make another rack because I'm cooking four, not two, molds.

Here we are, all loaded up.

This is Wednesday. All I'm doing today is cooking those blocks. I expect the heating

elements to burn out about 3pm. Then I'll have to scramble all night, trying to

wire a kiln that's too hot to touch.

I wonder what other people do for fun?

So… I had a hard time getting out of bed on Thursday. I expected another long, stressful

day. I had arranged for a substitute for the evening in GR, so I could stay at Zeeland

and finish the coin. This was my last night before Homecoming.

Actually, I had entertained the idea of coming home after school and going to bed,

and then getting up at 3 AM to finish the coin. That way I could dry the molds in

the kiln a bit longer. Michelle helped me out of that idea. I might need more time

after pouring and should probably start sooner.

When I got to school in the morning, I glanced in the kiln. I didn’t want to let

cold air in and chance cracks so I took a quick peek. The kiln was actually quite

cool. After shutting the door, I realized that the mold I saw looked pretty white.

That was very encouraging. Then I wished I had looked closer for cracks. I didn’t

want to open the door again. What difference would it make anyway? I turned up the

dial to 1250°.

It took quite a while to get up to temp and shut off. I probably should have switched

out those burned elements. After school, I turned it to 600° and was surprised that

it had to work about 20 minutes to get there. The thing must cool down fast. I wanted

the molds to be at 600° when I poured. I would turn it on at 600° again when I started

to cook the brass.

I planned to pour around 9 PM. That way the molds would have a good chance to dry

and I would be able to machine the castings and weld them before too late. So, then,

I would start the furnace around 8 PM. I took an hour nap in my car after school.

When I came back in, I made a ladle. I couldn’t pour from the crucible, like I always

do, because I would be alone this time. I cut some square tubing and welded it to

some flat steel.

Then I thought it should have a spout.

The plasma cutter is fun to work with. It cuts steel just like a razor cuts paper.

Welding is fun too.

This looked good. But it actually didn’t work so hot. It dribbled the metal out

too slow. I was afraid the little dribbles would freeze before the mold was filled.

After the first cast, I just spilled the metal out the back. That was faster.

While I was waiting for 8:00, I started to machine the ugly, screwed up slugs. I

wanted to practice and see what problems I might have. Actually, things went pretty

smoothly on this part.

Above, you can see that I switched the chuck jaws around to hold on to the bigger

diameter metal. And that I’m using parallel bars to hold the slug away from the

chuck. You wouldn’t want to turn on the machine with them in there.

I got the slugs as thin as I could and matched them up. Next step is to stick them

together. I thought about epoxy, but welding them would be best. I’m not real experienced

with welding brass. But it’s not as bad as aluminum. It’s rather violent when it

gets hot. I learned before that it’s best to ignore the noise and smoke and flying

stars, and feed the filler metal in fast. I’m going to need to weld my pig Peg,

so I thought I better practice here and now.

I welded up a cookie sheet, of sorts, and poured some brass into it. I did this

the other day. Tonight I sheared it up into practice pieces and some filler metal

sticks. I have brass filler rod, in the shape of heavy gage wire, but, when I weld

my pig Peg, I’ll want the filler color to be exactly the same as the casting. Tonight,

I want to see how these shears work in place of the filler rod. I was pleased at

how well it worked.

This is what the cookie sheet looked like after pouring hot metal into it. I used

this side for 3/8” thick sheet of brass. The other side gave me a 1/8” sheet, for

the filler metal. You can sort of see how deformed the cookie sheet got from the

heat. I probably won’t use it again for anything.

Like I said, I was pleased with how able I was with the welding. I stuck these two

pieces together in an edge joint, and figured that was easy enough. I was confident

enough to go right for the coin.

So, here’s what the practice slug looked like after welding and sanding. I’m satisfied.

I’d been stalling long enough. My stomach felt sick from the prolonged stress. I

tried not to think of what was coming next, and to forget about how important this

had become to me. I loaded the crucible with the prettiest brass I could find and

started cooking.

After this melted, I added more. I didn’t want to have any problems getting that

ladle full of pretty metal. I didn’t want to get a cup full of slag because the

thing wasn’t full enough. The slag floats.

When you add metal to an already melted charge, you need to be careful. Any moisture

can cause an explosion. Moisture, just from the air, will be found in abundance

in the slag that freezes on top of the bars we pour. I always hold the metal over

the mouth of the furnace for a brief time. It doesn’t take long. And I make sure

to suit up with leathers.

What I’m doing here is coating the steel skimmers and ladle with soot. If you don’t

do this, brass can stick to the steel and it’s very hard to get off. These skimmers

are new. They cost almost $50 each. You only use them once in the metal, and then

set them aside until you coat them again with soot. I used each of them twice. I

wanted to get as much of the slag off as I could.

Right after this, I was ready. It was time. I felt dizzy walking across the shop.

I tried not to think. I carefully set the molds out and started dipping and pouring

the hot metal. I was surprised at how much force it took to submerge the empty ladle

in that heavy brass.

Below, you see some hot metal. I was too late in getting the camera to show you

radiation. It always looks so cool when the stuff radiates, all yellow, and then

red.

I had a hard time getting myself to look at the results. I was too afraid. I needed

some good news. I figured the likeliest place to find it was the mold that had been

in the kiln the longest. This was the one with the cracks in it. My problems had,

up till now, been from water, not cracks. I had notice the metal agitating in that

particular mold, after pouring, but I couldn’t imagine that it would still be damp.

I thought that maybe gas was escaping from a crack. That couldn't be good, either.

But, it had been in that hot kiln since Tuesday morning. This was Thursday evening.

I never suspected moisture.

But you can see that I had big voids from steam. My heart sunk. Since I was sure

that this was as good as I would get, I had really no hope left. I figured the rest

of the night would be a clean up job.

This is the second casting I looked at. Although this is far from the quality I

expected when I started this job, it was a big relief to see the duck and lettering

so clearly. There are voids and detail is missing, but I can live with this. Now..

how about the chick?

I picked the chick mold that I thought was most likely to be successful. I picked

the one without the reinforcing and big crack. My heart sunk again. We have more

deep voids and lost detail. I lost all hope again, and felt rather panicky. We were

so close.

This last one came from the mold with the reinforcing and the big crack. I was relieved.

Although I would never show off a casting with all these flaws, you can make out

the logo. At last, I had something. I would be able to give this to my principal

I spent the next couple hours machining and welding. Then I polished the thing.

It doesn’t look good, like I wanted, but it will work. I can go home.

Here's what happened. At 7:00 AM on Friday, I emailed my principal saying that I

had a coin for her, but that I wanted to work on it until the end of the day. Then

I got a student with aptitude to produce several sand molds, using the waxed up

original as a pattern. We cast them and laid them aside. I ran the original down

to my principal, and left the new ones in the shop. After school, and after the

homecoming pep assembly, I returned and cut the gates off and polished the best

looking one. It wasn't bad at all. It was yellowier and, although lost more of the

detail, lacked the ugly voids. I found the principal and gave her this one, too.

I said that she could decide which one looked better and use that.

She said that the school board president had called early and wanted the coin so

that he could practice flipping it before the big game. As soon as I gave her the

first one, she sent it off to him.

I thought that was cool, that the president of the school board was asking for the

coin, and that the principal rushed it to him. It was an important thing. If I had

failed completely, like I almost did, it would have been embarrassing. But this

turned out ok. I'm quite relieved. I wish the quality was better, but I'm just a

shop teacher and an amateur artist. So what the heck!